2 suction cups that suck up the injected washing fluid in the ink remains.2 washing ports that inject printhead washing fluid towards the printheads during the washing sequence.The washing and purging processes that safeguard the printhead nozzles are performed in the cleaning station which has the following components: The cooling systems tubes carry the coolant in the black and gray electricity and communication tubes. The yellow ink delivery system or ids tubes hold the Dielectric Ink and Conductive Ink as It flows into the printheads. If you look at the group from the back service doors of the Dragonfly 3D PCB Printer, you can see a number of tubes. Printhead washing fluid is added to the Dielectric Ink and Conductive Ink printheads washing fluid tanks via the Dielectric Ink and Conductive Ink washing fluid funnels. It must be disposed of according to local regulations.

The waste container holds ink remains and used printhead washing fluid. During printing, the chuck is heated to 140° celsius and moves back and forth over the print axis. The ink flows from the main tanks to the Conductive Ink and Dielectric Ink secondary tanks and from there to the Conductive Ink and Dielectric Ink print heads via the yellow ink delivery system tubes.Įlectronic 3D printed devices are built layer by layer on a print substrate that is tightly attached to the chuck by vacuum. When filling this tank it is recommended to add up to 200 ccs of Dielectric Ink at a time. The left yellow tank is the main Dielectric Ink tank. When filling this tank it is recommended to add up to 100 ccs of Conductive Ink at a time. The right gray ink tank in the video is the main Conductive Ink tank. These are used for ink circulation and to enable cleaning the printheads. The pneumatic section includes air and vacuum pumps, tubes, and valves.

#Pcb printer plus#

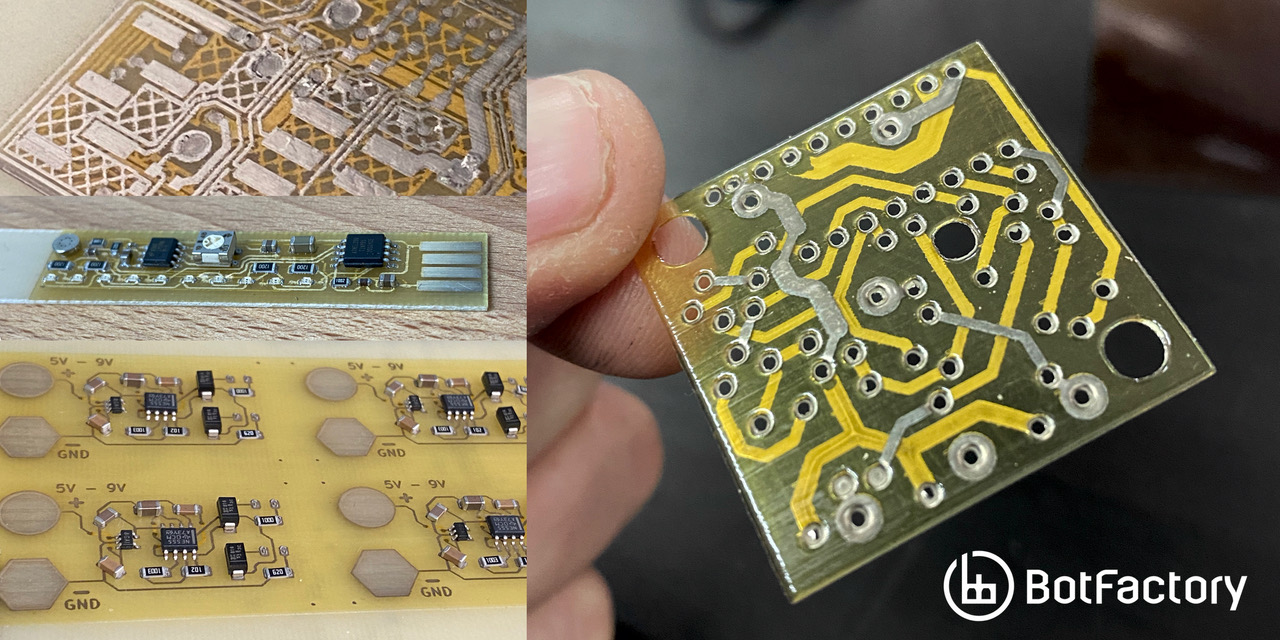

Actually allowed temperature is 30 degrees Celsius plus or minus 1.5 degrees celsius. The chiller is set to 30 degrees celsius. It is composed of a chiller, green coolant liquid, and tubes. The cooling system is responsible for ensuring the printheads do not overheat. The 3D PCB Printer is controlled and monitored by a specific application, which is installed on a dedicated PC. During the printing and the printhead cleaning sequences, the group moves back and forth in the group axis. It also has a camera that is used for print calibration purposes. The group holds the printheads and the UV lamp. The polymerized eye acts as insulation between the conductive elements and gives structure to the AME board. Once jetted onto the print tray, the Dielectric Ink is exposed to UV light which polymerizes and hardens it. This centers the nanoparticles together to form a material with a continuous conductive pattern.ĭielectric Ink is a monomer-based ink. The nanosilver particles that remain on the tray are then exposed to the heat of iron. As the ink is jetted onto a hot printing tray, its liquids evaporate. Each printhead has 512 nozzles through which the inks are jetted.Ĭonductive Ink is made of advanced silver nanoparticles that are suspended in a solvent and other liquids. In our case, both inks have been developed exclusively for the Dragonfly system developed by Nano Dimension. Conductive and Dielectric InksĪt the heart of the system there are two printheads that simultaneously jet: Thanks to the video below, we can have an overview of the 3D PCB Printer and its components. The 3D PCB Printer prints planar and 3D electromechanical devices based on designs created in ECAD software. The 3D PCB Printer additively manufactures functional electronic devices.

0 kommentar(er)

0 kommentar(er)